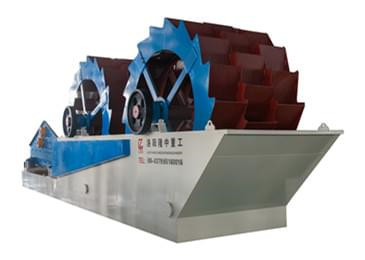

Dual Wheel Sand Washing Machine

The dual wheel sand washing machine integrates two set wheel sand washing machines with the dewatering screen and hydrocyclone separator, which is specially designed for washing, grading, recycling, and concentrated dewatering of coarse and fine materials.

Dual wheel sand washing machines can widely process sandstone and quartz sand, aggregate, coal, ore, tailing, etc. The sand can be cleaned, dehydrated and graded twice, which will greatly reduce the content of mud and impurities and water in sand and improve the sand quality.

Dual wheel washing machine is is upgraded and developed based on the original sand washing and recycling equipment.

Or Call Us Now +86-18736301510

1. Multiple functions, integrate sand washing, fines recycling, coarse and fines concentrated dehydration in one.

2. By connecting the two sand washers in series and the spray water pipes arranged around them, the material can be cleaner fully.

3. The fines recovery device can recover more than 90% of fines in the overflowing muddy water during sand washing, to make the finished sand grading well, and effectively improve the economic benefits.

4. If the muddy water treatment system is configured later, the pressure of concentrated filter press can be greatly reduced, so that the entire process can be optimized.

Features & Benefits

1. Multiple functions, integrate sand washing, fines recycling, coarse and fines concentrated dehydration in one.

2. By connecting the two sand washers in series and the spray water pipes arranged around them, the material can be cleaner fully.

3. The fines recovery device can recover more than 90% of fines in the overflowing muddy water during sand washing, to make the finished sand grading well, and effectively improve the economic benefits.

4. If the muddy water treatment system is configured later, the pressure of concentrated filter press can be greatly reduced, so that the entire process can be optimized.

Working principle

The material after pre-treatment enters first cleaning tank, under the constant rotation and stirring of impeller, material is full mixed into water, and the impurities on the surface of material are taken away by water to make material cleaner.

Then the impeller picks up material from the water and leaks water and impurities, and transfers the qualified material to the second tank and repeat the process in first tank, so the materials is further cleaned twice.

Then enter to dewatering screen, and remove a large amount of water through the vibration of dewatering sieve, so that the material is more convenient to store and transport. The material leaked in water tank enters slurry pump through overflow device, and is pumped to the hydrocyclone for concentration and recovery. After concentration, the qualified materials are returned to dewatering screen for dehydration. The excess muddy water and impurities enter the return tank.

Specifications

| Model | Feeding Size (mm) | Capacity (t/h) | Impeller Size (mm) | Hydrocyclone (mm) | Screen Panel (mm) | Power (kw) | Overall Size (mm) |

| 2DL40 | ≤10 | 20-40 | 1800*800 | 250*2 | 1200*2400 | 32.4 | 7120*3650*2160 |

| 2DL60 | ≤10 | 30-60 | 2600*1200 | 300*2 | 1500*3000 | 44 | 8900*5560*2750 |

| 2DL80 | ≤10 | 40-80 | 3000*1600 | 300*2 | 1800*4200 | 52 | 11600*5860*3370 |

| 2DL100 | ≤10 | 60-100 | 3000*1600 | 350*2 | 1800*4200 | 63 | 11600*5860*3370 |

| 2DL150 | ≤10 | 100-150 | 3600*2000 | 300*4 | 2400*4200 | 97 | 12800*6560*3970 |

| 2DL200 | ≤10 | 120-200 | 3600*2400 | 350*4 | 3000*4800 | 126 | 12800*7150*4170 |

| 2DL250 | ≤10 | 160-250 | 4200*3000 | 300*6 | 3600*6000 | 164 | 14400*7740*4860 |

Contact Form

Get in touch with us and one of our team will be with you shortly.

Disclaimer:

All informations contained in this site is provided on an "as is" basis with no guarantees of usefulness or timeliness. For exact specifications, please contact with us: export@lylzzg.com