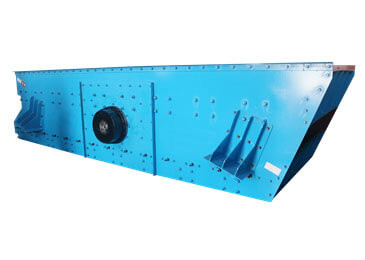

Circular Vibrating Screen

Y series circular vibrating screen is a classic, universal and standardized screening equipment.

The motion track of this series screening machine case is circular. According to the use, it can be divided into light and heavy. The screen surface of the screening machine has a single layer and double layer structure.

Longding circular vibrating screen adopts cylindrical eccentric shaft vibration exciter and partial block to adjust amplitude, material sieve line length, screening specifications, reliable structure, strong excitation force, high screening efficiency, low vibration noise, and durability. , convenient maintenance, safe use and so on.

The vibrating screen is widely used in product grading in mining, building materials, transportation, energy, chemical and other industries. Long Ding circular vibrating screen can be used for screening coal, limestone, gravel, gravel, metal or non-metallic ore and other materials.

Or Call Us Now +86-18736301510

1. The circular vibrating screen has novel structure, advanced technical parameters, large processing capacity and high screening efficiency.

2. The vibration motor is used as the excitation source, which is easy to use and maintain.

3. The vibrator is lubricated with bearings and oiled, and the external block is eccentric. The excitation force is large, the bearing load is small, the temperature is low, and the noise is small.

4. It adopts spring steel braided mesh or punched sieve plate, which has long service life and is not easy to block holes.

5. The whole disassembly and assembly of the vibrator is convenient for maintenance and replacement, which greatly shortens the maintenance period.

6. The circular vibrating screen adopts rubber vibration isolation spring, which has long service life, low noise and stable over-resonance area.

Features & Benefits

1. The circular vibrating screen has novel structure, advanced technical parameters, large processing capacity and high screening efficiency.

2. The vibration motor is used as the excitation source, which is easy to use and maintain.

3. The vibrator is lubricated with bearings and oiled, and the external block is eccentric. The excitation force is large, the bearing load is small, the temperature is low, and the noise is small.

4. It adopts spring steel braided mesh or punched sieve plate, which has long service life and is not easy to block holes.

5. The whole disassembly and assembly of the vibrator is convenient for maintenance and replacement, which greatly shortens the maintenance period.

6. The circular vibrating screen adopts rubber vibration isolation spring, which has long service life, low noise and stable over-resonance area.

Working principle

This series of circular vibrating screen is mainly composed of screen box, screen mesh, vibrator and damping spring, etc. The vibrator is installed on the side plate of the screen box and rotated by the motor through the triangle belt to produce centrifugal inertia force and force the screen box to vibrate. If users do not have special requirements, Y and 2Y type for textile screen, YH type for punching screen, all kinds of screen surface can meet the screening efficiency, long life, no hole plugging requirements.

The circular vibrating screen or called round vibrating screen is mounted in a seat. The adjustment of the screen inclination can be achieved by changing the height of the spring support. The motor can be installed on the left side of the screen frame, and can be installed on the right side of the screen frame. If there is no special requirement, the manufacturer installs the product according to the right side of the material movement direction.

Y series circular vibrating screen is imported from foreign technology and has the characteristics of high screening efficiency, scientific and reasonable structure, high strength and rigidity of the whole machine, stable operation, sturdy and durable, low noise and convenient maintenance. According to the different needs of users, the series of vibrating sieve screens can be equipped with various types of screen surfaces such as wire mesh, rod, casting, welding and punching to meet the needs of different industries.

Specifications

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Screen Area (m²) | Power (kw) | Overall Size (mm) |

| 2YK1548 | 0-200 | 0-160 | 1500*4800 | 7.2 | 11 | 5000*2900*2900 |

| 2YK1860 | 0-200 | 0-200 | 1800*6000 | 10.8 | 15 | 6200*3400*3500 |

| 3YK1860 | 0-300 | 0-200 | 1800*6000 | 10.8 | 22 | 6200*3400*4100 |

| 2YK2160 | 0-200 | 0-250 | 2100*6000 | 12.6 | 22 | 6200*3700*3500 |

| 3YK2160 | 0-300 | 0-250 | 2100*6000 | 12.6 | 22 | 6200*3700*4100 |

| 2YK2460 | 0-200 | 0-300 | 2400*6000 | 14.4 | 22*2 | 6200*4100*3800 |

| 3YK2460 | 0-300 | 0-300 | 2400*6000 | 14.4 | 30*2 | 6200*4100*4400 |

| 2YK2472 | 0-200 | 0-300 | 2400*7200 | 16.8 | 22*2 | 7400*4000*4000 |

| 3YK2472 | 0-300 | 0-300 | 2400*7200 | 16.8 | 30*2 | 7400*4100*4600 |

| 2YK3072 | 0-200 | 0-300 | 3000*7200 | 21.6 | 30*2 | 7400*4700*4100 |

| 3YK3072 | 0-300 | 0-300 | 3000*7200 | 21.6 | 30*2 | 7400*4700*4700 |

| 3YK3672 | 0-300 | 0-350 | 3600*7200 | 25.92 | 37*2 | 7400*5400*4700 |

Contact Form

Get in touch with us and one of our team will be with you shortly.

Disclaimer:

All informations contained in this site is provided on an "as is" basis with no guarantees of usefulness or timeliness. For exact specifications, please contact with us: export@lylzzg.com