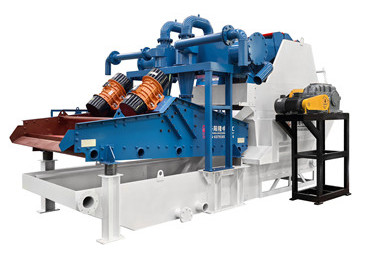

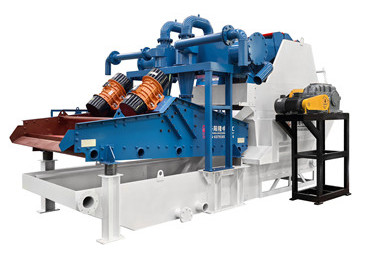

Sand Washing Machine

This sand washing machine is designed based on sand washer and sand recycling system and adopted foreign advanced technology. This machine main parts include: XSD wheel sand washer, high frequency dewatering screen, high pressure cyclone, cleaning tank, return box, high pressure wearable slurry pump, motors, etc.

The machine has simple structure and multiple function, and is widely used for crushed sand, river sand, lake sand or sea sand washing, screening, recycling and dewatering.

Or Call Us Now +86-18736301510

1. With the advantages of sand washing, fine sand recycling, cleaning materials than the traditional sand washing machine cleaner.

2. Low energy consumption, energy saving and environmental protection.

3. Long service life and low maintenance cost.

4. Simple installation, small footprint.

5. Special models can be customized according to different needs.

Features & Benefits

1. With the advantages of sand washing, fine sand recycling, cleaning materials than the traditional sand washing machine cleaner.

2. Low energy consumption, energy saving and environmental protection.

3. Long service life and low maintenance cost.

4. Simple installation, small footprint.

5. Special models can be customized according to different needs.

Working principle

When the sand washing machine is working, the electric motor runs slowly with the impellor after decelerated by the belt, decelerator and gears wheel. The sand and gravel enters the cleaning tank from the feeding port,and is scrubbed and grined with water through the bucket moving,then the cleaned sand be put out by sand storage web groove and fed onto polyurethane screen for dewatering.

The overflow of water tank(including a large number of fine sand, mud, dust and other impurities) is extracted to cyclone separator by slurry pump,the fine sand is collected by the centrifugal force of cyclone, then fed to the polyurethane screen for dewatering from the apex spray.Finally, the qualified mixed coarse and fine sand is conveyed to form stock pile.

Specifications

| Model | Feeding Size (mm) | Capacity (t/h) | Impeller Size (mm) | Hydrocyclone (mm) | Screen Panel (mm) | Power (kw) | Overall Size (mm) |

| DL40 | ≤10 | 20-40 | 1800*800 | 250*2 | 1200*2400 | 29.4 | 5800*5000*1950 |

| DL60 | ≤10 | 30-60 | 2600*1200 | 300*2 | 1500*3000 | 40 | 5800*5560*2750 |

| DL80 | ≤10 | 40-80 | 3000*1600 | 300*2 | 1800*4200 | 46.5 | 7950*6200*3700 |

| DL100 | ≤10 | 60-100 | 3000*1600 | 350*2 | 1800*4200 | 57.5 | 7950*6200*3700 |

| DL150 | ≤10 | 100-150 | 3600*2000 | 300*2 | 2400*4200 | 89.5 | 8500*6800*3700 |

| DL200 | ≤10 | 120-200 | 3600*2400 | 350*4 | 3000*4800 | 115 | 7950*7400*4100 |

| DL250 | ≤10 | 160-250 | 4200*3000 | 300*6 | 3600*6000 | 149 | 8580*8020*4860 |

Contact Form

Get in touch with us and one of our team will be with you shortly.

Disclaimer:

All informations contained in this site is provided on an "as is" basis with no guarantees of usefulness or timeliness. For exact specifications, please contact with us: export@lylzzg.com